Highway Maintenance - Road Maintenance

Definition / Objectives:

Preserving and keeping each type of roadway, roadside, structures as nearly as possible in its original condition as constructed or as subsequently improved and the operation of highway facilities and services to provide satisfactory and safe transportation, is called maintenance of Highways.

The various maintenance function includes;

- Surface maintenance

- Roadside and drainage maintenance

- Shoulder and approaches maintenance

- Snow and ice control

- Bridges maintenance

- Traffic service

- Highway maintenance is closely related to the quality of construction of original road.

- Insufficient pavement or base thickness or improper construction of these elements soon results in expensive patching or surface repair.

- Shoulder care becomes a serious problem where narrow lanes force heavy vehicle to travel with one set of wheels off the pavement.

- Improperly designed drainage facilities, mean erosion or deposition of material and costly cleaning operation or other corrective measures.

- Sharp ditches and steep slopes require manual maintenance as compare to cheap maintenance of flatter ditch and soil by machine.

- In snowy country, improper location extremely low fills and narrow cuts leave no room for snow storage, creating extremely difficult snow removal problems.

|

1. Surface maintenance of Roads

-

Pavement maintenance and rehabilitation programs, restore riding quality and maintain the structural integrity of the pavement over its full design life.

Asphalt concrete pavements are subjected to various types of pavement distress or Failure these include.

|

i. Alligator Cracking:

A series of interconnecting or interlaced cracks caused by fatigue of the asphalt concrete surface under repeated traffic leading. [Cracking is due to foundation movement at subgrade]

|

ii. Block Cracking:

Cracks forming large interconnected polygon usually with sharp corners or angles. These cracks are generated by hardening or shrinking e.g. asphalt or reflection cracking for underlying layers such as cement treated base.

|

iii. Transverse Cracking:

-

Cracks approximately at right angle to the pavement center line. These may be caused by hardness and shrinkage of asphalt or differential thermal stresses of asphalt concrete or may be reflection cracking.

|

iv. Longitudinal Cracking:

v. Raveling:

-

Wearing away the pavement surface caused by dislodging of aggregate particles and binders. This is usually a result of insufficient asphalt binder in the mix or stripping of asphalt from particles of aggregate.

|

vi. Drip Track Raveling:

-

Progressive disintegration of the surface between wheel paths caused by dripping of gasoline oil from vehicle.

|

vii. Bleeding or Flushing (Fatting Up):

- The exuding of bitumen on to the pavement surface causing reduction in skid resistance. Bleeding is generally caused by excessive amount of asphalt in the mix or low air void content. It occurs in the mix in hot weather.

|

viii. Corrugations:

Due to instability of base or poor original riding surface (plastic movement of pavement)

|

ix. Pot Holes:

When cracks become deep.

|

x. Ruts:

Depressions formed under the wheel due to heavy load, this causes consolidation, deformation or plastic flow.

|

General surface maintenance:

- For maintenance of gravel roads blading and occasional resurfacing is required.

- For surface treatments of low type bituminous surface in maintenance of roads; Patching, seal coating or possible loosening oiling, re mixing and relaying are involved.

- For high type bituminous concrete and Portland cement concrete, the Removal and replacement of failure areas and resurfacing are approximate treatment methods for highway maintenance.

- Use same material and methods for road surface maintenance as fas as possible.

- Highway Maintenance must be planned for rapid performance and to cause least possible disruption or hazard to traffic.

|

2. Roadside and Highway Drainage maintenance

-

Depends on the characters of road side where the roadside is grassy it must be mowed; cutting, ploughing or spraying with weed killer must be done.

- If there is dry grass fire hazard burning, plowing must be done.

- When back slope is covered with bush, trimming must be done to increase the sight distance and clearance of road.

- Control of side slope erosion by mulching, seeding etc.

- Picking up litter, thrown or blown along roadside or wayside area a Routine work.

- Drainage of Highway Maintenance: Keeping ditch, culvert and other drainage structure, clean and ready to carry next flow water. Sediments deposited during period of heavy flow must be removed badly eroded channel and dikes properly protected to prevent recurrence.

|

3. Shoulders:

-

Depend on the surface character of these areas

- SOD shoulders must be moved and occasionally bladed down to the level of the roadway so that water is not trapped in the traveled way. Gross must be kept in good condition.

- Shoulders protected by bituminous blankets or surface treatments same as for roadway surface.

- Gravel and earth shoulders that leaves a drop off at the pavement edges creates a serious accident hazard, hence, should be corrected by reconstruction, resurfacing or other appropriate means.

- Due to continuous wetting and drying of shoulder, edge joints result between lane and shoulder which may cause settlement of pavement due to entrance of water in sub grade soil. It can Repaired by filling the joint with sand and asphalt concrete

|

4. Snow and ice control:

-

Ice forming on the roadway reduces coefficient of friction between tires and surface, which makes vehicle control almost impossible. In highway maintenance we can apply abrasive to heavily traveled roadway and street.

Suitable materials that can be used are clean and sharp sand, cinders and washed stone screening.

|

5. Bridge maintenance:

6. Traffic services:

-

Include stripping, sign repair and maintenance (particularly needed for repair after stormy weather.

|

Surface Treatment of Highways - Highway Surface Maintenance

-

Although the best type of surface course is pre-mix carpet for highway maintenance;

- Intensity of traffic is not very high.

- the pro-mix mixers are not easily available due to long transportation or technical reasons.

- when the cost is high.

The surface treatment methods are employed. The surface treatment may be single or multiple.

|

Single Surface Treatment:

-

Is wearing course in which the bituminous material is sprayed and the aggregate is placed uniformly over the applied bitumen mineral. The thickness of such layer approximate the nominal size of aggregate used.

|

Multiple Surface Treatment:

-

(Double or Triple) is a wearing surface in which a course aggregate is placed on bitumen coat (prime coat) already applied, followed by spraying of bitumen and then by subsequent application of finer aggregate over a second bitumen coat. Generally the minimum size of the smallest aggregate is one of the aggregate used in the preceding application usually thickness of single layer approximately maximum size of aggregate.

|

Function of surface treatment:

- to provide long lasting economical surface for granular base road having light and medium traffic volume.

- To prevent entry of surface water into old pavement that have been weathered or cracked.

- It improve the skid resistance of bitumen surface where the surface has polished under traffic.

- To provide temporary cover in case of delayed incomplete pavement.

In Highway Maintenance, For good surface treatment it is necessary that;

- Base course is well prepared to its profile and is made more free from pot holes and ruts.

- Excellence of surface dressing depends upon the correct proportion of binder aggregate.

- Before laying that first surface dressing coat, the base should be made free from all dust loose soil etc.

In all bituminous construction it is necessary that the newly surface posses a bond with the existing base at the interface. It is also necessary that the base is nearly impervious.

|

highway drainage is done efficiently. Water that falls on the road way follows laterally or obliquely from it, under the influence of cross slope. Or superelevation in pavement and shoulder. A suitable value of cross fall for paved roads is about 3% for carriage way with a slope of 4-6% for shoulders. And increased cross fall for the carriage way e.g. 4% is desirable if the quantity of the final shape of the road surface is likely to be low for any reason,

highway drainage is done efficiently. Water that falls on the road way follows laterally or obliquely from it, under the influence of cross slope. Or superelevation in pavement and shoulder. A suitable value of cross fall for paved roads is about 3% for carriage way with a slope of 4-6% for shoulders. And increased cross fall for the carriage way e.g. 4% is desirable if the quantity of the final shape of the road surface is likely to be low for any reason,

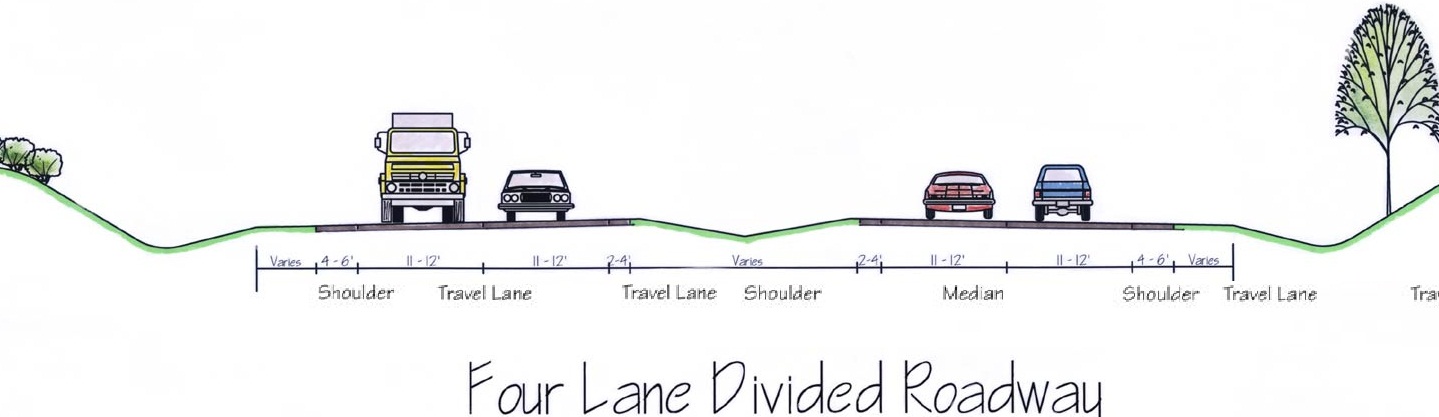

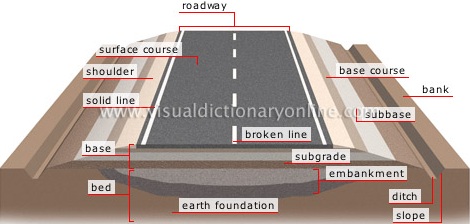

Road Cross Section.

Road Cross Section.